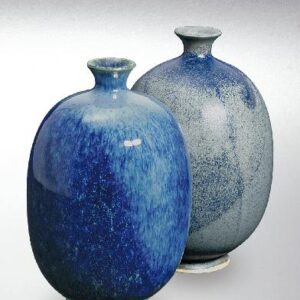

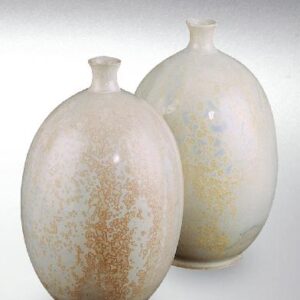

TerraColor Turquoise Glaze

$53.00

Product number: 9652

Firing range: 1200 – 1260°C

Colour: Turquoise

Finish: Matt

Type: Effect

Acid Resistance: No – Not Food Safe

Dishwasher resistance: Good

Luminous, semi-matt turquoise with delicate iridescence.

front: 1250°C; rear: 1230°C

Glaze Mixing

We recommend sieving the powder before mixing to break it up, adding back any speckles for speckled glazes; we recommend using a powered hand mixer (drill with paddle spiral mixer or hand held blender for smaller lots) then sieve to ensure no agglomerated dry powder remains, and then rest it for two hours to allow any air to be absorbed and not create bubbles, pin holes when fired. For some glazes it is best to soak the powder with a little water first.

Dipping: Mix S/ware to double cream or slightly thinner to match the porosity of the bisque. Mix E/ware to single cream. Typical dipping recipe is E/ware 750/790gm liquid to 1000gm powder; S/ware 690/700gm liquid to 1000gm powder. Recommended liquid is 85% water to 15% medium or 2% SCMC cellulose solution. If you have problems keeping in suspension add 2% bentonite to the dry powder next time. This is a starting point – you may need to add more liquid to get the consistency you like.

Brush On: Typical brush on recipe is 100gm powder to 40gm water and 50gm medium or 90gm of 2% SCMC Cellulose solution. For some dense glazes you may have to put in as much as 105gm of liquid.

If you have already mixed a quantity of glaze and it is falling out of suspension then you can use calcium chloride as a flocculent, particularly in E/ware glazes. Dissolve one flake in a small amount of hot water and then add to slop one drop at a time.

Tips:

Slow bisque firing helps the gasses escape – fast bisque firing can trap gasses that then try to escape during the glaze firing – splitting the piece, bloating, pin holing, peeling off the glaze etc. Wiping off the salts after bisque firing can stop those salts reboiling creating pin holes and glaze peeling during the glaze fire. Too high a bisque fire can close off pores of smooth clays stopping the glaze from grabbing hold and risk it crawling off or running. Too thick a mix for the pore size can also make it run.

- Description

- Additional information

- Finish

- Acid Resistance

- Dishwasher Resistance

Description

Description

Glaze Preparation

While our liquid glazes have been prepared ready for brush application and usually only need to be shaken up before use, experience has shown that glaze preparation for our powder glazes must be carried out according to the following steps:

- Provide the required mixing water according to the label (original unit) in a correspondingly large container. Since we only give guidelines (as a range), you should start with the lower range value – after all, it is easier to add water afterwards instead of removing it.

- If you want to blend the glaze with powder additives like glaze binders, then we recommend to pre-mix the glaze powder with the weighed amount of additive by using a spoon.

- Pour glaze powder into the mixing water with as little dust as possible. Usually a cone of powder forms afterwards, which protrudes above the water surface.

- Let the glaze powder soak in for a few minutes and mix the slurry well with a hand mixer or electric blunger.

- Stoneware glazes are raw glazes. These should be sieved, especially for application by pouring, dipping and spraying. This avoids glaze defects. To do this, use a standard 900 mesh glaze sieve and pour the glaze slip into it. With a harder bristle brush, lumpy components can be passed through with a little effort. Some glazes contain harder effect components (speckles), which cannot be pushed through the sieve. These components must be put back in the glaze container. Earthenware glazes are mainly frit glazes. Wet sieving is usually not necessary when applying, particularly by means of a brush.

- If necessary dilute the glaze slip with water in order to achieve the required consistency. Add liquid thickening (flocculant) agents if necessary.

- Leave the glaze to stand overnight so that the glaze binders (which you might have added later) can swell in order to develop their full effect.

- Stir the glaze briefly (there must be no more sediment) and use it.

If you want to use e.g. the spraying technique, so that the glaze powder has to be grinded in a glaze mill, any effect components (speckles) that may be present must be sieved out before the milling and then added again afterwards. Glazes with cadmium inclusion pigments must not be processed in a glaze mill (you can find information on this for every glaze under acid resistance).

Additional information

Additional information

| Weight | 2.5 kg |

|---|---|

| Dimensions | 10 × 12 × 23 cm |

Finish

Finish: Matt

Acid Resistance

Acid Resistance: No

Dishwasher Resistance

Dishwasher Resistance: Good

If fired ceramic pieces are cleaned in a dishwasher, the glaze is exposed to the moving detergent solution with high temperature, which leads to an attack of the glaze surface showing evidence in either becoming more matt or, as in many cases, in getting an iridescent gloss.